1. Limited Ceiling Void Space

One of the most common challenges in Singapore’s built environment is the extremely limited ceiling void available for services. With architects and developers aiming for maximized floor-to-ceiling heights, the service zones between slab and false ceiling are often compressed to 300–500mm, or even less in retrofitted buildings. This space must accommodate:

- HVAC ducts (supply, return, exhaust)

- Electrical trunking and cable trays

- Sprinkler piping and plumbing

- Lighting and access panels

As a result, routing ductwork becomes a complex coordination task requiring multi-trade BIM modeling and on-site adjustments.

2. Congested M&E Service Corridors

In high-rise commercial and mixed-use developments, mechanical risers and horizontal service corridors are often overcrowded. Ducts must compete for space with:

- Electrical and ICT services

- Water and sanitary piping

- Fire protection systems

- Structural beams and bulkheads

This leads to routing conflicts, awkward offsets, and frequent changes from the original layout. Installers must also maintain minimum clearances for maintenance access, making efficient space planning critical.

3. Restrictions from Structural Elements

Singapore buildings often feature precast beams, transfer girders, and post-tensioned slabs, limiting the locations where ducts can pass through or be suspended. Core walls, fire-rated zones, and access hatches further restrict routes.

Installers face the challenge of:

- Avoiding core drillings that breach fire compartments.

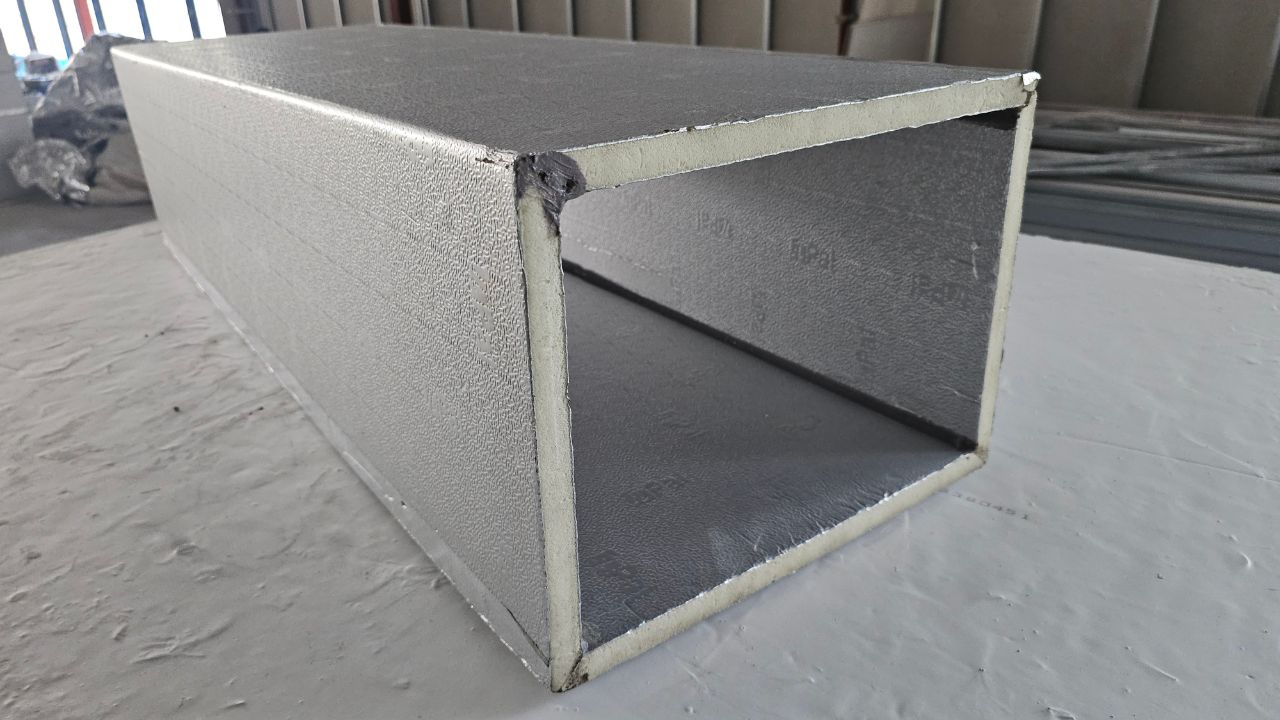

- Designing duct shapes (e.g., flat oval or slim rectangular) to pass through tight zones.

- Working around limited hanger and support anchor points.

4. Noise Control and Airflow Balance

In low ceiling heights, duct velocities must often be reduced to control noise, especially near occupied zones. But reducing velocity requires larger duct cross-sections, which worsens the space constraint.

Balancing:

- Duct size

- Airflow performance

- Sound attenuation

- Spatial limitations

…becomes a tough design and installation problem, often requiring custom fittings or split duct routes.

5. Safety and Coordination Risks

Tight ceiling spaces increase:

- Installation difficulty and time, as workers maneuver large ducts in confined areas.

- Risk of clashes, particularly when as-built conditions differ from design drawings.

- Fire safety concerns, especially where duct penetrations affect rated walls or ceiling fire protection systems.

Close coordination with structural, electrical, and fire protection teams is essential to avoid rework, delays, and compliance issues.

Conclusion

Ducting installation in Singapore’s space-constrained buildings is far more than just a mechanical task. It’s a complex coordination and problem-solving challenge. The use of BIM modeling, early clash detection, and modular duct systems like PID or pre-insulated panels can help mitigate these difficulties. Still, on-site flexibility, skilled installers, and close inter-trade communication remain critical for successful delivery.