In the HVAC industry, air leakage from duct systems is one of the most significant contributors to energy loss, comfort complaints, and system inefficiency. To mitigate these issues, the DW143 standard, published by the Building Engineering Services Association (BESA), provides industry-recognized procedures for duct air leakage testing.

This article outlines the purpose, methodology, and compliance expectations based on the DW/143 standard, widely adopted across projects in Singapore and internationally.

What is DW/143?

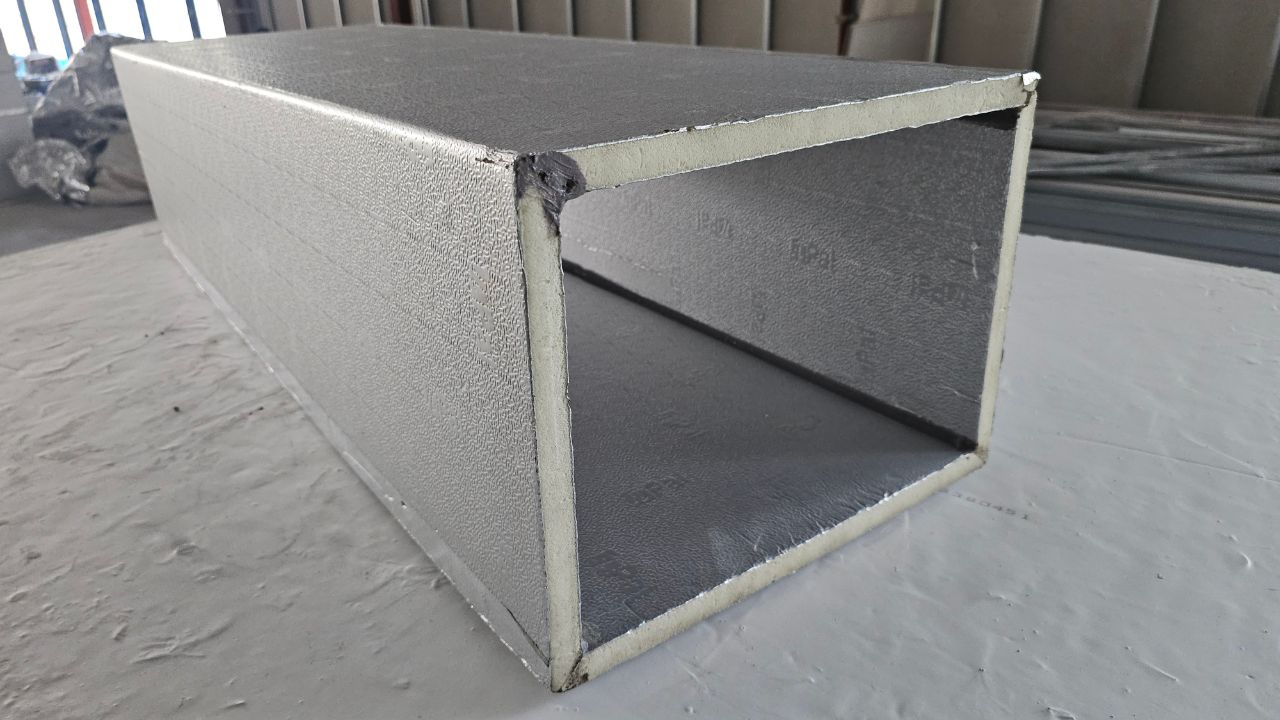

DW/143 is the authoritative guide for measuring air leakage in sheet metal ductwork systems. It defines:

- Test procedures

- Classification of ductwork by pressure class

- Maximum allowable leakage rates

- Equipment setup and test section requirements

The aim is to ensure ducts are built and installed to meet tightness performance levels, avoiding excessive air loss that could lead to energy wastage, comfort issues, or inadequate ventilation.

Why Duct Leakage Testing is Important

- Energy Efficiency: Leaky ducts force fans to work harder, increasing energy consumption.

- System Performance: Air may not reach the intended zones, affecting cooling or ventilation.

- Compliance: Many building authorities and green certifications (e.g., BCA Green Mark in Singapore) require tight ductwork.

- Indoor Air Quality: Leaks in return ducts can draw in dust or pollutants from ceiling voids or risers.

DW143 Duct Pressure Classes and Leakage Limits

The standard classifies ducts based on operating pressure:

| Class | Max Pressure (Pa) | Typical Application | Max Leakage (L/s/m²) |

| A | ±500 | General low/medium pressure HVAC | 0.027 x P^0.65 |

| B | ±1000 | Medium pressure supply systems | 0.009 x P^0.65 |

| C | ±2000 | High-efficiency systems | 0.003 x P^0.65 |

| D | ±3000 | Specialized high-pressure ducts | 0.001 x P^0.65 |

(P is the static pressure in Pascals applied during the test)

Note: Singapore projects typically test to Class B or C standards depending on the system type (e.g., Class C for supply air ducts in cleanrooms or medical environments).

Leak Test Procedure (DW143 Methodology)

1. Select a Test Section

- Must be representative and include joints, bends, and fittings.

- Length typically 10–30 meters or at least 10 m² of duct surface area.

2. Temporarily Seal Ends

- Use blanking plates, foam, or film to close off open duct ends, branches, or take-offs.

3. Connect Testing Equipment

- Attach calibrated blower/fan to pressurize the duct.

- Use manometers or digital sensors to monitor internal pressure.

- Flow meter measures how much air is added to maintain pressure (i.e., leakage rate).

4. Perform the Test

- Gradually increase pressure to the class requirement.

- Once stable, record leakage flow rate and pressure.

- Plot results and calculate leakage rate per m².

5. Evaluate Compliance

- Compare measured leakage with DW/143 allowable rate.

- If failed, inspect and seal leaks before retesting.

Common Leakage Points

- Poorly sealed joints

- Gaps around access doors or dampers

- Unsealed duct take-offs

- Incomplete or damaged duct sealing tape

- Improper installation of flexible ducts

Integration with Singapore Standards

- In Singapore, SS 553:2016 recommends testing for systems operating above 1000 Pa or as required by the QP/consultant.

- Duct leak testing is commonly enforced in commercial, institutional, and green-certified buildings.

- Often tied to TOP clearance or Green Mark scoring.

Conclusion

Duct leakage testing is more than a formality. It’s a performance assurance step that improves system efficiency, reduces operational costs, and supports environmental goals. By following DW143 testing procedures, engineers and contractors in Singapore can ensure their duct systems meet both international best practices and local compliance requirements.