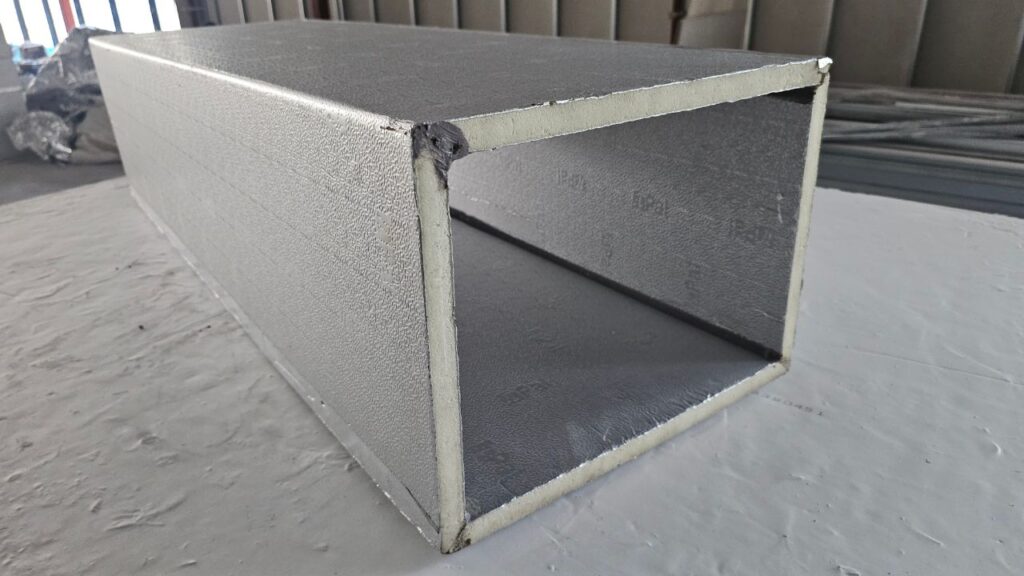

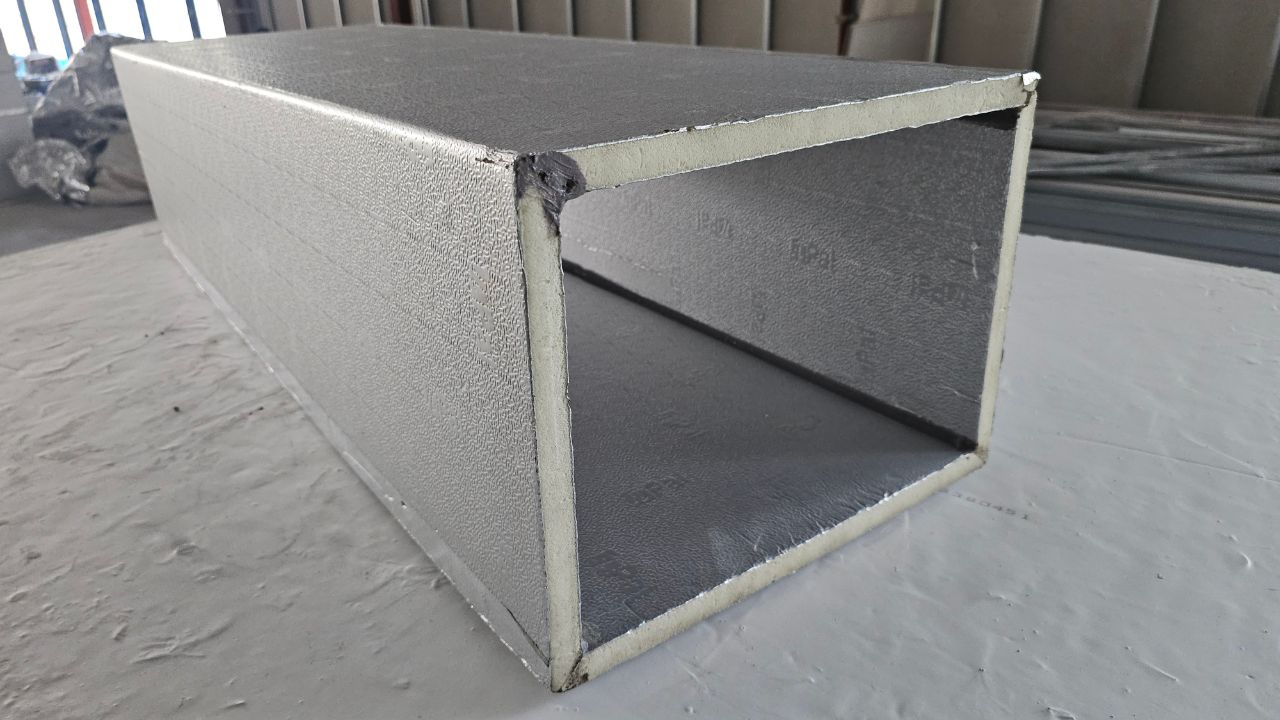

PID (Pre-Insulated Ducting) systems are widely used in modern HVAC installations due to their light weight, clean finish, and built-in thermal performance. The insulation core in PID duct panels is typically PIR (Polyisocyanurate), a high-performance foam with:

- Thermal conductivity (λ): 0.020 W/m·K

- Density: 45 kg/m³

- Excellent fire resistance and moisture resistance

This low thermal conductivity means PIR insulation achieves better thermal performance with less thickness compared to traditional materials like fiberglass or elastomeric foam.

Assumed Environmental Conditions (Singapore or similar climate)

- Ambient temperature: 34°C

- Supply air temperature (inside duct): 12°C

- Relative Humidity (RH): 70%–90%

- Target: Prevent condensation by keeping surface temperature above the dew point

Dew Point Reference Table (at 34°C ambient)

| Relative Humidity | Approx. Dew Point |

| 70% | ~28°C |

| 80% | ~30°C |

| 90% | ~32°C |

To prevent condensation, the surface temperature of the duct exterior must remain above the dew point.

Recommended PID Insulation Thickness (PIR Core, λ = 0.020 W/m·K)

| Application Condition | Recommended PID Panel Thickness |

| Indoor supply or return air ducts (RH ≤ 70%) | 20 mm |

| Indoor supply ducts in high humidity areas (RH 70–80%) | 20–25 mm |

| Outdoor ducts or areas with RH > 80% | 32 mm |

| Ducts exposed to direct sunlight or rain | 32 mm with external protection |

🔹 Why 20mm Works Indoors

At λ = 0.020 W/m·K, 20mm PIR insulation provides sufficient thermal resistance to prevent condensation in most air-conditioned indoor environments, especially where the dew point stays below 28°C.

🔹 Why 32mm Is Needed Outdoors

In outdoor or plantroom environments, or where RH > 80%, 32mm PIR is recommended to ensure the duct surface temperature stays safely above the dew point (≥ 32°C), and to protect against thermal gain from hot surroundings.

Conclusion

Thanks to the high thermal efficiency of PIR insulation (λ = 0.020 W/m·K), PID ducting requires less thickness to perform better than conventional materials. Use:

- 20mm panels for typical indoor air-conditioned spaces

- 32mm panels for high-humidity, outdoor, or exposed environments

Always verify project-specific requirements with local mechanical specifications or building codes (e.g., BCA, SS 553, or ASHRAE).