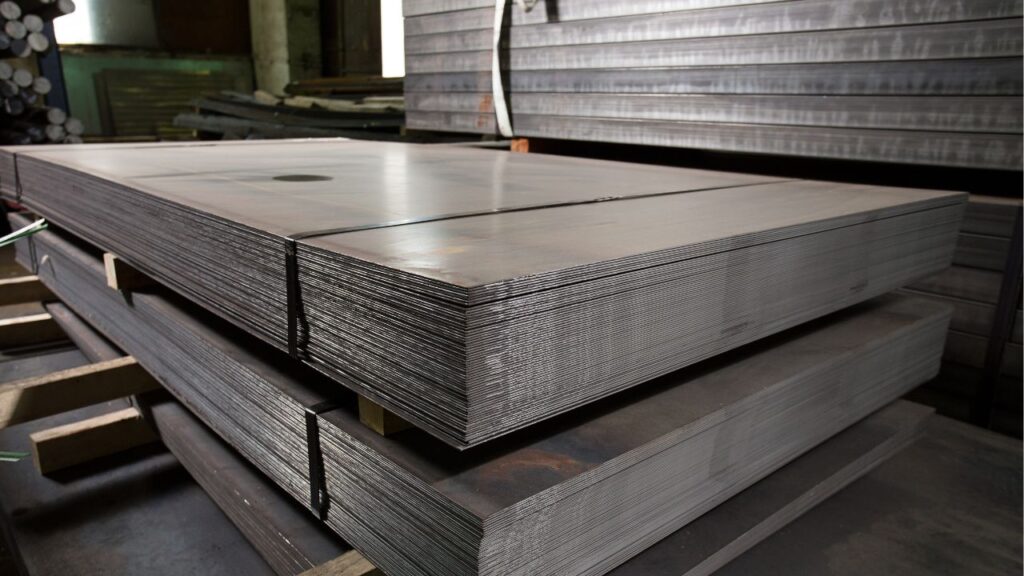

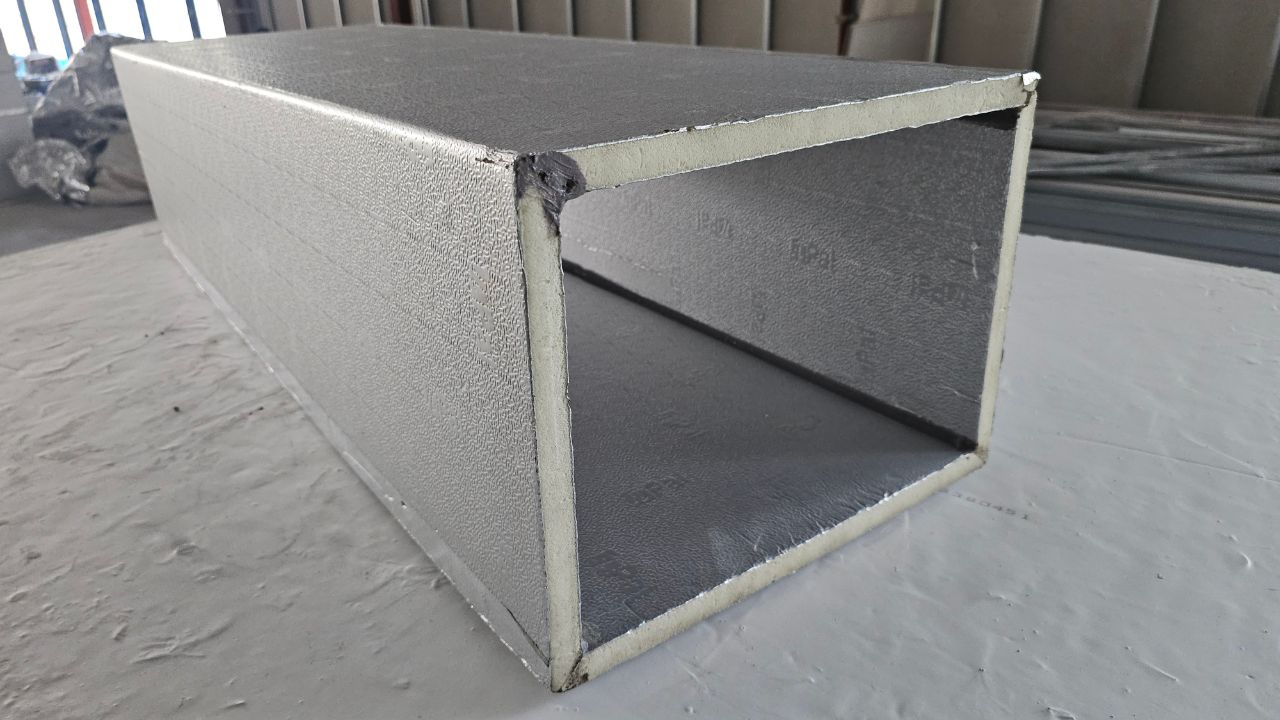

When designing and fabricating HVAC duct systems, choosing the right metal sheet thickness is critical to ensure structural integrity, durability, and cost-effectiveness. Ducts need to withstand internal air pressure, external forces, and environmental conditions without deforming or leaking. This is where British SWG (Standard Wire Gauge) standards come into play.

Below is an explanation of how duct size determines the appropriate sheet thickness, joint type, and bracing based on the industry-standard table.

What Is SWG (Standard Wire Gauge)?

SWG (Standard Wire Gauge) is a British standard that defines metal thickness. The smaller the SWG number, the thicker the sheet. For example:

- SWG 24 = 0.60 mm thick

- SWG 22 = 0.80 mm thick

- SWG 20 = 1.00 mm thick

- SWG 18 = 1.20 mm thick

Duct Thickness by Size Range

The table outlines the required sheet metal thickness for rectangular ducts based on their maximum dimension (width or height):

🔹 Up to 300mm

- SWG 24 (0.60mm)

- Joints & Bracing: 25mm x 25mm x 3mm angle iron used for both transverse joints and bracing.

🔹 301mm to 460mm

- SWG 24 (0.60mm)

- Same joint and bracing as above.

🔹 461mm to 760mm

- SWG 22 (0.80mm)

- Joints/bracing: Heavier 25mm x 25mm x 4mm angle iron.

🔹 761mm to 1070mm

- SWG 22 (0.80mm)

- Same joint and bracing as the previous category.

🔹 1071mm to 1400mm

- SWG 20 (1.00mm)

- Upgraded to 38mm x 38mm x 4mm angle iron for both joints and bracing.

🔹 1401mm to 2151mm

- SWG 20 (1.00mm)

- Bracing placed closer at 0.7m from joints due to larger duct size.

🔹 Above 2151mm

- SWG 18 (1.20mm) – thickest sheet used for very large ducts.

- Reinforced with same 38mm x 38mm x 4mm angle irons and tighter bracing (0.7m spacing).

Why Is Thickness Important?

- Structural Strength: Thicker sheets provide more rigidity and prevent duct collapse under pressure.

- Vibration & Noise Control: Thicker materials reduce noise caused by vibration.

- Durability: Thicker ducts resist damage from impacts or corrosion over time.

- Compliance: Adhering to thickness standards ensures the duct system meets building and fire safety codes.

Conclusion

Choosing the correct sheet metal thickness based on duct size is essential for building a reliable and efficient HVAC system. By following the standards outlined, using the right SWG, angle iron joints, and bracing distances, you ensure the system performs well under various conditions. If you’re planning a duct system, always consult qualified professionals and follow recognized standards to get the best balance of cost, durability, and safety.